Rubber Spacer, Screw, Foaming Strip

BC0001, BC0002/3, BR0003, C6001

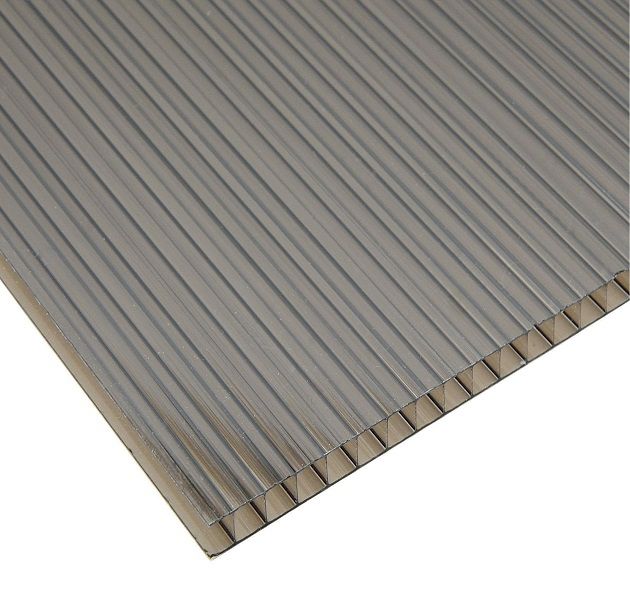

Polycarbonate sheet commonly used in application of skylight are found to covered with a layer a oil stain and dust.

The biggest problem is the impact of thermal expansion and contraction, PC board expansion coefficient formula.

Thermal expansion and contraction is the main impact for causing the sheet to crack.

Therefore Polycarbonate coefficient expansion formula to be : (7x10-5/°C).

For example plate temperature 23°C and 15°C, 38°C temperature difference.

For example, Polycarbonate sheet which is stored at the temperature degree celsius of 23 and 38, 15 degree Celsius to be the difference. Method of calculation to be 3500 x 0.00007 x 15°C = 3.675 mm Which means calculation for 15°C difference to be ; 3500 + 3.675 = 3503.675 mm

For example 1:

Installation of Polycarbonate sheet in the status of (expansion) during the hot mid day will cause sound made by Polycarbonate sheet when it (contracts) in the evening time due to inappropriate flexibility.

For example 2:

If installation of Polycarbonate sheet in the contraction status during evening period of time, Polycarbonate will form an uneven proportion surface as the sheet expands during the day. As the stress which form in Polycarbonate due to expansion and contraction, this will cause polycarbonate sheet to crack in a period of time.

Special rubber spacer are applicable to avoid polycarbonate sheet from cracks due to expansion and contraction once and for all.

Rubber spacer consist of upper and lower lead hole which comes with different diameter. Upon the tightening of screw with lead hole onto Polycarbonate sheet, it generates expansion and apply appropriate close integration. Ensure no leakage and no silicon application is required.

Product Reference

| Item | Color | Reference Code |

|---|---|---|

| Rubber Spacer (for Solid sheet) | Black | BC0001 |

| Rubber Spacer(for Twin-wall sheet) | Black | BC0002/3 |

| Screw | Silver | BR0003 |

| Foaming strip | White | C6001 |

Applications

- Roofing, Skylight, Balcony, Walkway, Overhead Bridge, Ceilings covering, Car shield, etc.

Certificate

ISO 9001.

- Related Products

Polycarbonate Profile (H Type)

AA-03-H6000, AA-03-U6000, AA-05-H6000

Sun Asia's connecting Polycarbonate profiles could connect sheets for covering of large areas...

DetailsPolyethyene Rubber Tape

It could adjust the height of sheet to have more smooth surface and prevent to be cracked and broken.

Details- Files Download

Rubber Spacer, Screw, Foaming Strip - Rubber Spacer, Screw, Foaming Strip | Heat Resistant & UV Coated & Multiwall Polycarbonate Sheets Manufacturer | Sun Asia Enterprise Co., Ltd.

Located in Taiwan since 1990, Sun Asia Enterprise Co., Ltd. has been a heat resistant polycarbonate sheet manufacturer. Their main products, including Rubber Spacer, Screw, Foaming Strip, Polycarbonate Sheets, Polycarbonate Roofing Sheets, Polycarbonate Panels, Clear Polycarbonate Sheets, Plastic Sheets, Polycarbonate Greenhouse Sheets, Light Diffuser Panels, Twin Wall Polycarbonate Sheets and Multiwall, which are ISO 9001 certified.

Based in Taiwan, SUN ASIA is one of the primary polycarbonate sheet suppliers since 1990. Multiwall polycarbonate sheets, solid polycarbonate sheets, embossed polycarbonate sheets and frosted polycarbonate sheets with other wide range of polycarbonate sheet solutions for traditional construction, civil engineering, interior design and lighting industries. Safe and secured with competitive price. Over 30 years of extruded polycarbonate manufacturing industry. Specialized in outdoor durable building materials.

SUN ASIA has been offering customers high-performance solid polycarbonate sheets, both with advanced technology and 35 years of experience, SUN ASIA ensures each customer's demands are met.